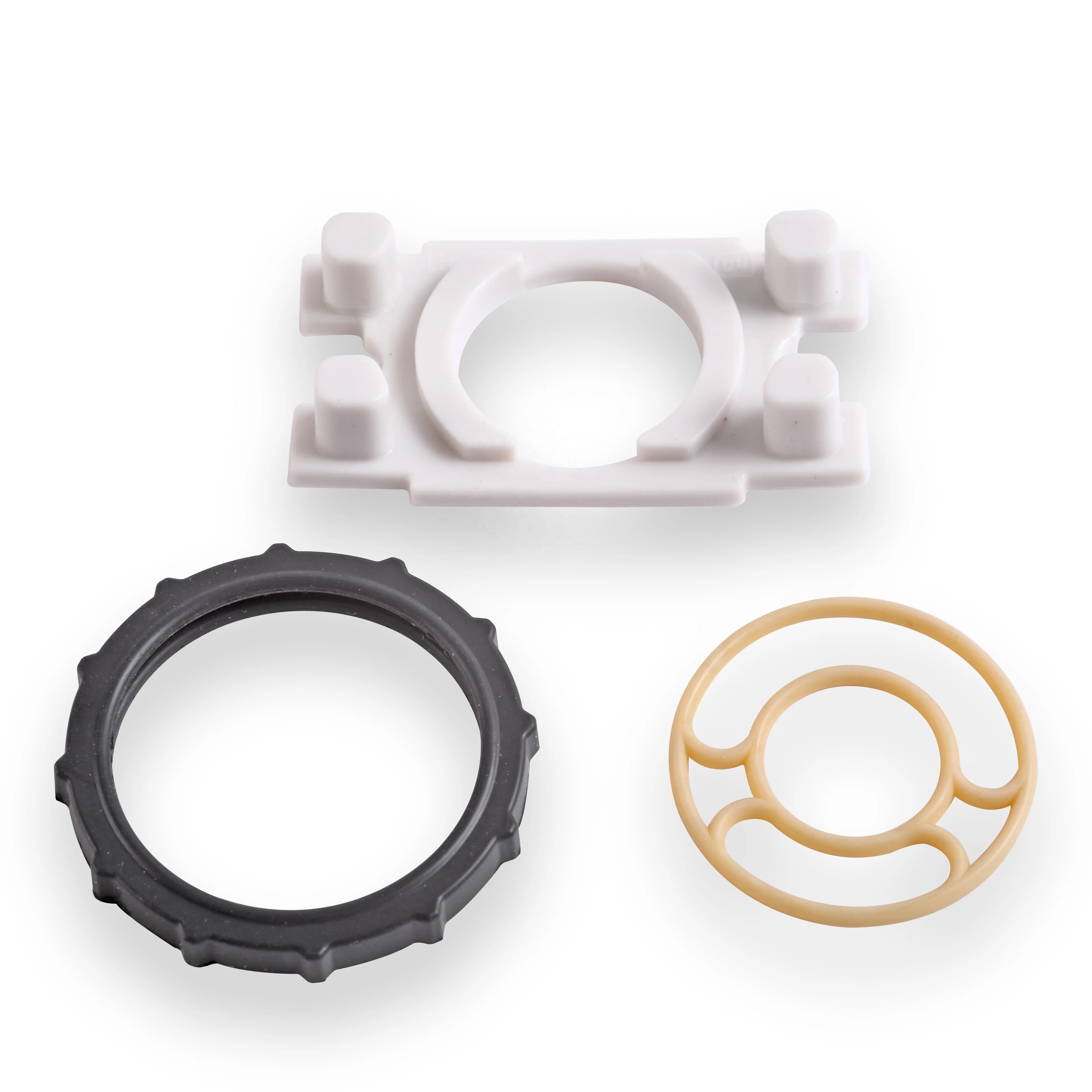

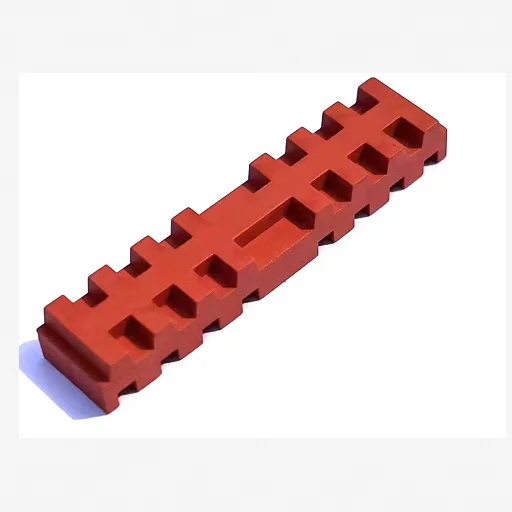

Rubber Gaskets are one of the few parts which play an important role in factories and big buildings. They help to keep parts in place and prevent fluids or gases from escaping where they belong. Ever seen a rubber band? Kind of like a big, flat rubber gasket. Because there are so many rubber gasket types and sizes, they can be used in virtually every type of machine or equipment.

In this case, rubber gaskets are found all over the place in various locations like factories hospitals schools and supermarket. But their purpose is really just to hold two things tightly together. On pressing both sides to form a seal, that action seals the deal protect fluids, gases and certain solids from seeping through where those belong in. Eg. in a water bottle with lid, there could be Rubber gasket inside the cap It separates the two plates and avoids water spillage when you tip your bottle. Rubber gaskets have even been put into use in protecting factory workers from inadvertently faulting chemicals or fluid which would be harmful to humans as well the environment. For that reason rubber gaskets are so important in so many different ways.

There are many important aspects to consider when deciding on a rubber gasket for any job. The rubber is important too, as some rubbers are much better in various conditions. You should also take into account temperature and pressure, as well as chemical compatibility of the gasket. Moreover, the number and sorts of locales that require fixing become possibly the most important factor. Whenever you are looking for the right type of rubber gasket, it would be wise to seek guidance from an expert. This allows them to be able to give you helpful advice for the best gasket that is fit for your needs.

Rubber gaskets are excellent for sealing because they can form a tight seal with two mating surfaces, including where the surfaces have bends or even their surface is rough. Rubber is flexible and can be cut to fit around other parts. This will help fill in the area where it is connected and make a solid seal that will not let out any water. And because rubber gaskets can be manufactured in large volumes to custom specifications, they find applications across various sectors. Tailoring gaskets to the specific needs of a job means companies can make sure their equipment performs as it should.

Good rubber gaskets will allow the pieces of machinery and equipment to function well. A rubber gasket can withstand the heat and high pressure your pump will operate under at all times not to mention any chemicals it may come into contact with. This means fewer breakdowns, and less chance of leaks from the machine. The right rubber gasket option can minimise the time, money and resources wasted during cleaning or necessary downtime. Such improvement in performance can result to more seamless functions leading into a greater efficiency among the company.

Rubber gaskets are not unlike several other parts of a machine in that, and they too may succumb to wear out soon — thus making it essential for you to replace them promptly. But, there are a few tricks to make them last far longer. Proper cleaning and inspection can prevent dirt and dust from accumulating on the gasket. A result of this, is increased wear on the gasket and that can have an adverse effect too. Gasket -- and, fitting it correctly and installing/ securing properly is also important in working good. Proper maintenance of rubber gaskets can help businesses keep their machines operational for longer, which is beneficial to them in the long run.